Metal. Ceramic. Plastic.

Forged with Light.

Dax Research delivers advanced 3D printing, CNC machining, and laser welding solutions. Backed by a decade of expertise and partners like Schaeffler, we help bring complex designs into real-world production.

Services

What we do

From Metal 3D printing and machining to laser plastic welding

Consulting

Expert guidance on your laser plastic welding project.

From applications to production solutions.

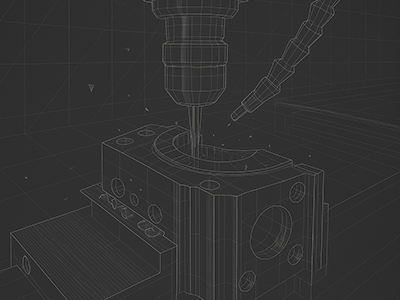

CNC Machining

Precision CNC machining services for complex parts and components.

3D Printing Service Center

Professional 3D printing services with advanced materials and technologies.

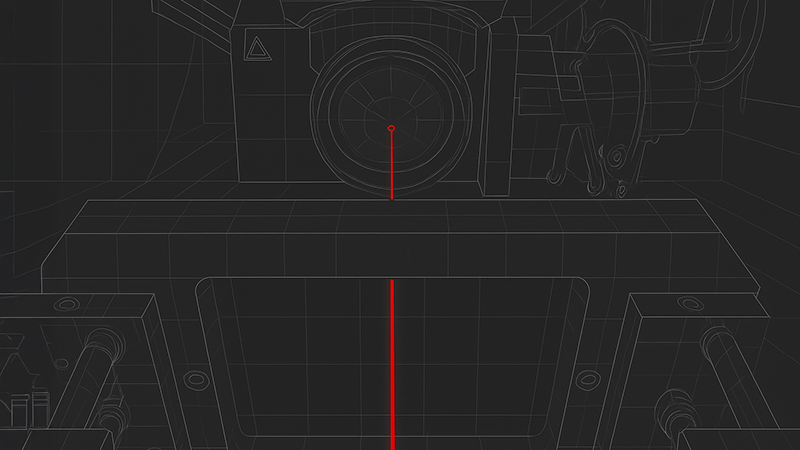

Omnifusion3D Printer

Multi-material 3D metal printing system with precision laser fusion technology.

Laser Welding Tools & Applications

Advanced laser welding solutions for plastic components with exceptional precision.

Rapid Manufacturing

Streamlined production processes for faster time-to-market with reduced waste.

Show Room & Lab

Visit our facility to see our equipment in action and collaborate on projects.

Industries We Serve

Explore our expertise across various industrial sectors.

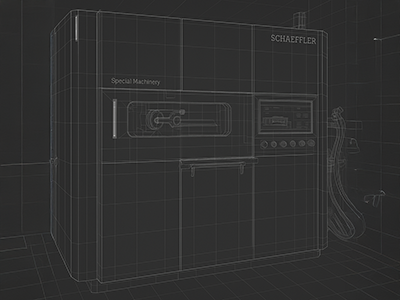

Introducing the Omnifusion3D Printer

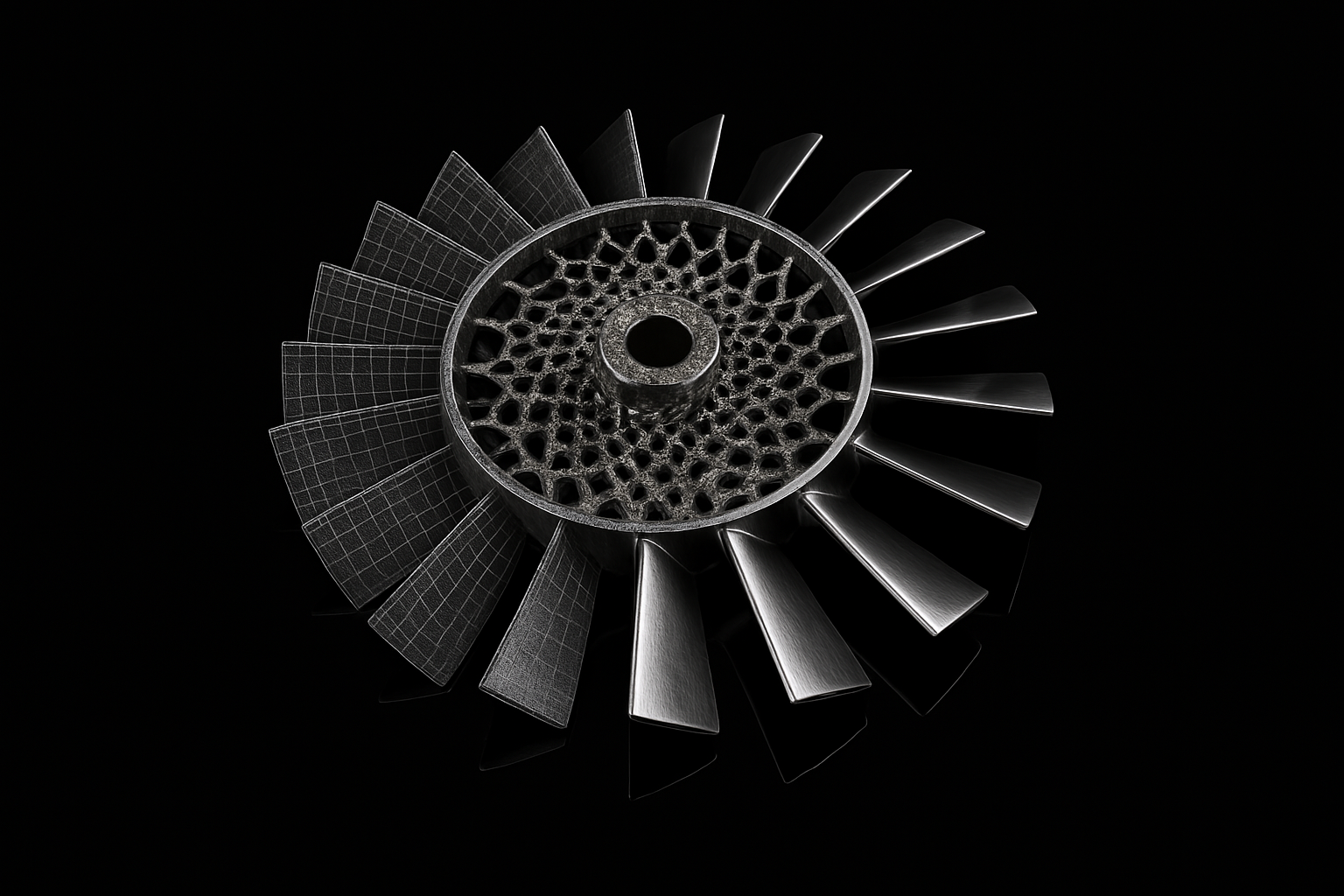

Developed by Schaeffler, the Omnifusion3D represents the next generation in multi-material additive manufacturing

Unique Capabilities

- •Precision laser fusion with unprecedented accuracy

- •Advanced material compatibility for unique combinations

- •Innovative functional integration in products & tools

- •Flexibility in form for individual, free design

- •Reduced lead time, especially for tools & prototypes

Multi-Material Advantages

In many areas, additive manufacturing has established itself as an alternative to conventional production methods. Multi-material 3D printing opens up almost unlimited possibilities, offering:

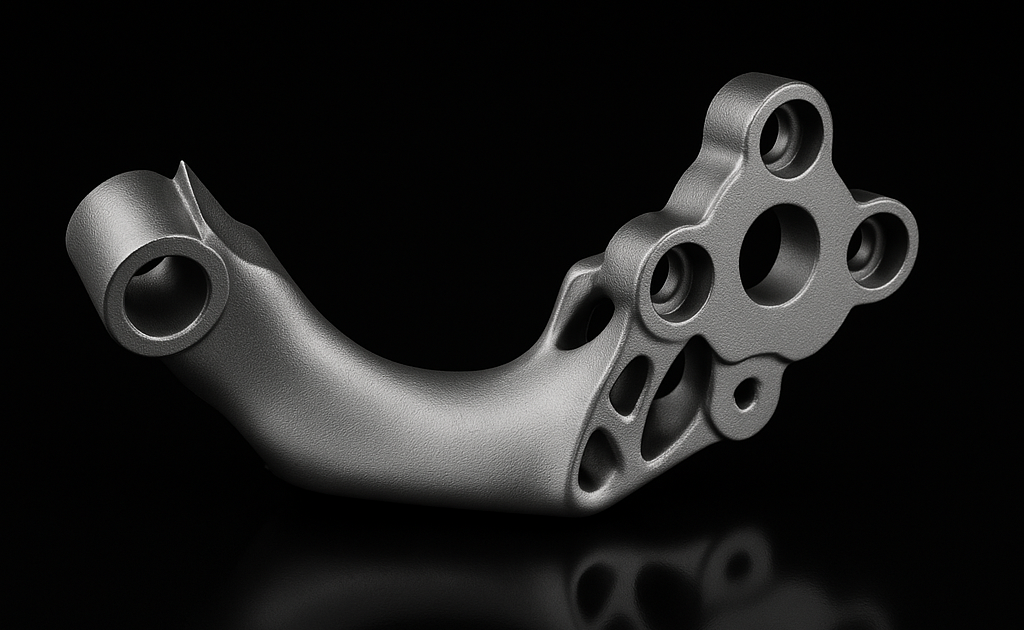

- •Simplified production of components with complex geometries

- •Reduced material consumption and waste

- •Increased energy efficiency in production

- •More environmentally friendly material options

Technical Specifications

| Specification | Details |

|---|---|

| Deposition width | 250 mm / 4.53 inches |

| Layer thickness | 40 µm - 150 µm |

| Recoating speed | Up to 50 mm/s / 1.97 inches/s |

| Integrated powder containers | 750 ml per drum (3 drums) |

| Recoater size | 480 x 361 x 182 mm / 18.9 x 14.2 x 7.2 inches |

| Powder pixel resolution | 300μm for recoater and die filling platform |

Omnifusion3D Applications

Tool Components

Injection molding insert

- • High thermal conductivity

- • Fast availability of near-end-shape semi finish

- • Low waste of tool material

Welding brackets

- • High wear resistance and thermal conductivity

- • Minimal material waste

Products

Heat sink

- • Organic structure

- • High surface area for improved cooling

- • High thermal conductivity with lightweight housing

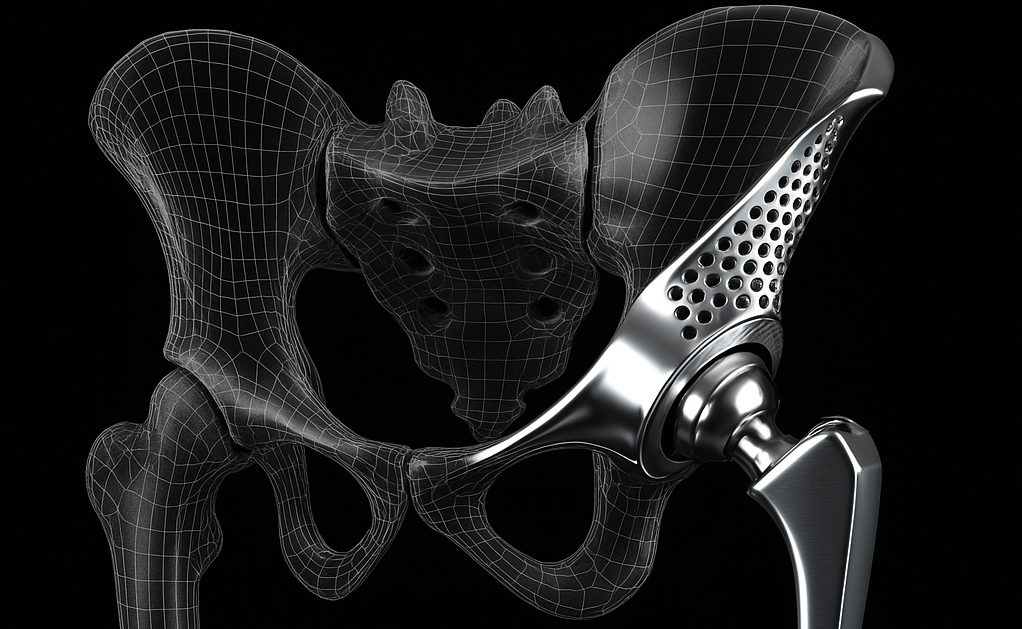

Medical implants

- • Innovative joint materials

- • Right material at the right place

Prototypes

Hydrogen applications

- • Increased integration level

- • Reduction of precious materials

- • Controlled porosity

Electric motor coil

- • Fully flexible design

- • Fast component availability

Get in Touch

Have questions about our services or want to start a project? Fill out the form below and our team will get back to you shortly.