Metal 3D

Printing Solutions

Production-grade, multi-material parts in days—powered by Laser Powder Bed Fusion up to 250 mm³.

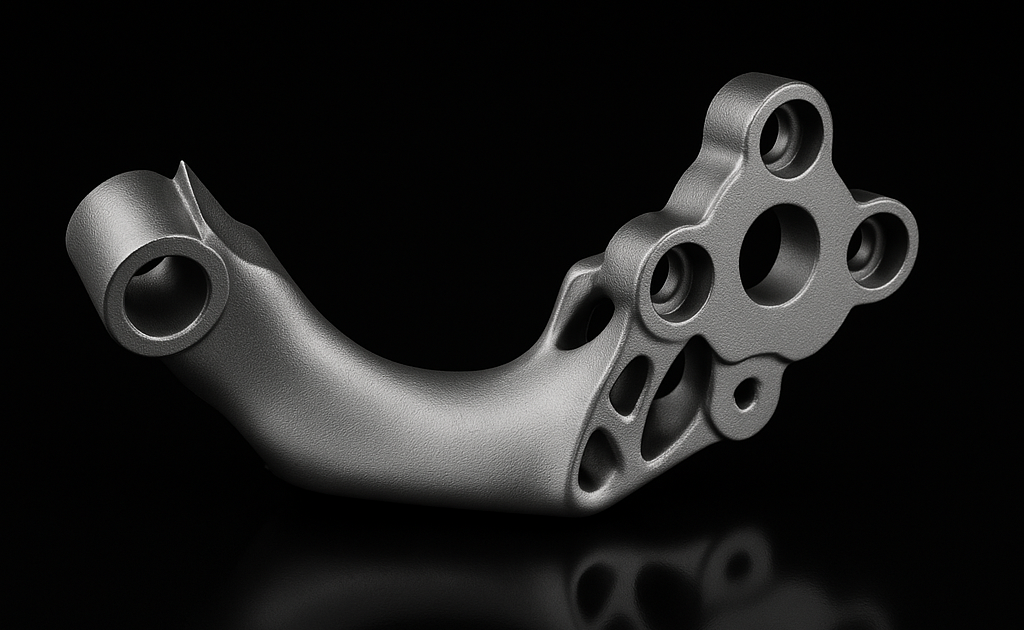

Design Freedom

Print internal channels & lattices impossible with CNC.

Multi-Material Fusion

Combine copper, steel & ceramics—layer by layer.

Rapid Turnaround

Quote in minutes, ship parts in as little as 5 days.

Production Quality

≤ 99.8 % density, full CMM & CT inspections included.

Industries We Serve

Explore our expertise across various industrial sectors.

More Than Manufacturing

From concept to production, we provide end-to-end metal 3D printing services to meet your manufacturing needs.

Discover & Scope

We review your CAD, target specs, and cost drivers.

Prototype & Validate

Rapid LPBF builds plus HIP, machining, and full test reports.

Scale & Deliver

Locked process, recurring builds, and on-demand inventory.

Introducing the Omnifusion3D Printer

Developed by Schaeffler, the Omnifusion3D represents the next generation in multi-material additive manufacturing

Unique Capabilities

- •Precision laser fusion with unprecedented accuracy

- •Advanced material compatibility for unique combinations

- •Innovative functional integration in products & tools

- •Flexibility in form for individual, free design

- •Reduced lead time, especially for tools & prototypes

Multi-Material Advantages

In many areas, additive manufacturing has established itself as an alternative to conventional production methods. Multi-material 3D printing opens up almost unlimited possibilities, offering:

- •Simplified production of components with complex geometries

- •Reduced material consumption and waste

- •Increased energy efficiency in production

- •More environmentally friendly material options

Technical Specifications

| Specification | Details |

|---|---|

| Deposition width | 250 mm / 4.53 inches |

| Layer thickness | 40 µm - 150 µm |

| Recoating speed | Up to 50 mm/s / 1.97 inches/s |

| Integrated powder containers | 750 ml per drum (3 drums) |

| Recoater size | 480 x 361 x 182 mm / 18.9 x 14.2 x 7.2 inches |

| Powder pixel resolution | 300μm for recoater and die filling platform |

Omnifusion3D Applications

Tool Components

Injection molding insert

- • High thermal conductivity

- • Fast availability of near-end-shape semi finish

- • Low waste of tool material

Welding brackets

- • High wear resistance and thermal conductivity

- • Minimal material waste

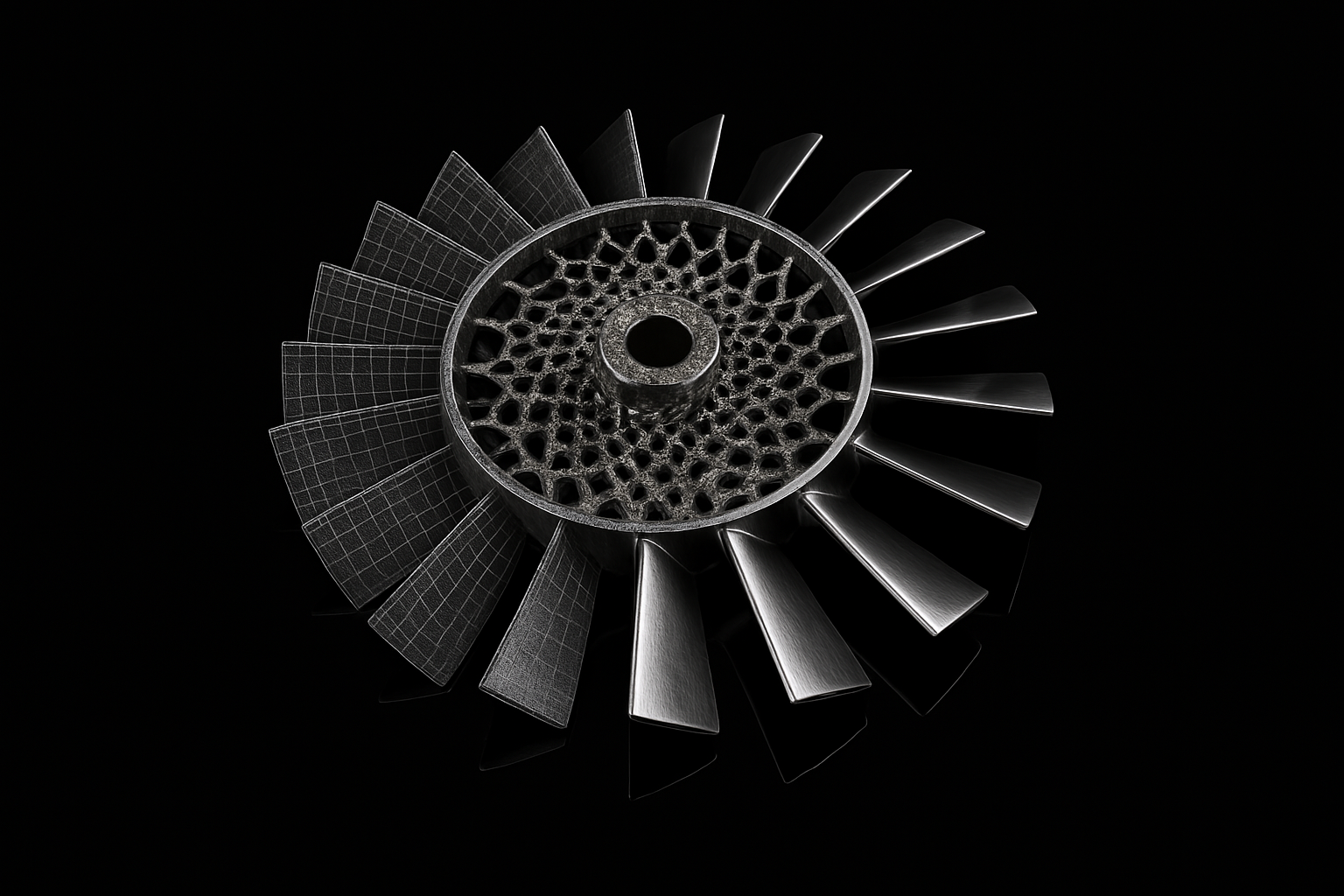

Products

Heat sink

- • Organic structure

- • High surface area for improved cooling

- • High thermal conductivity with lightweight housing

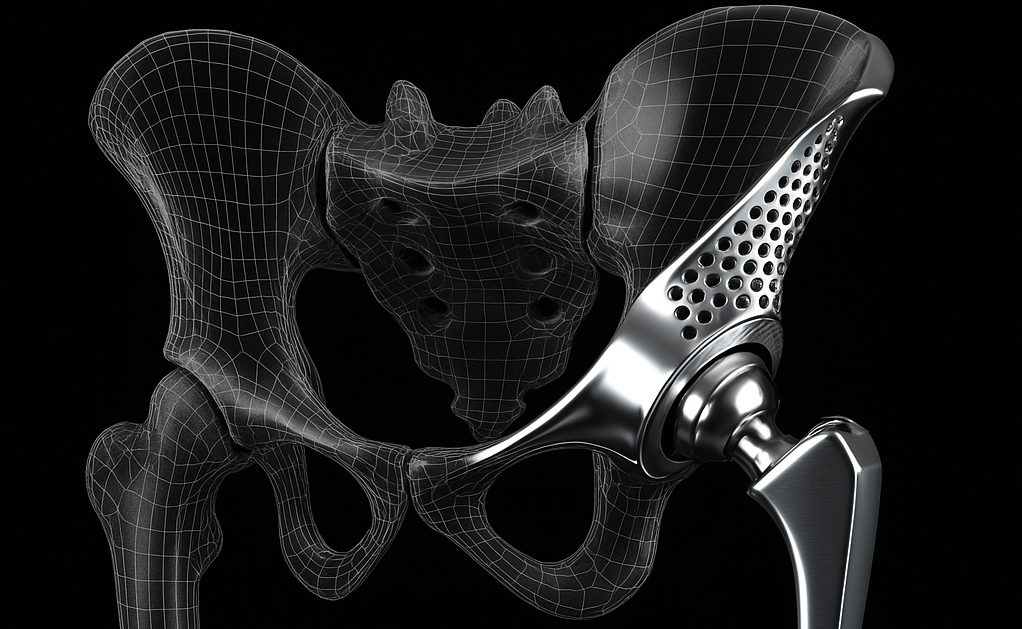

Medical implants

- • Innovative joint materials

- • Right material at the right place

Prototypes

Hydrogen applications

- • Increased integration level

- • Reduction of precious materials

- • Controlled porosity

Electric motor coil

- • Fully flexible design

- • Fast component availability