Industrial-Grade Multi-Material

3D Printing

The OmniFusion 3D unites metals and ceramics in a single build platform.

300 µm resolution

Industry-leading pixel size for ultra-fine details.

Multi-Material Fusion

Combine copper, steel & ceramics—layer by layer.

40-200 µm Layer Thickness

Optimised layers deliver aerospace-grade strength.

≤ 99.8 % density

Wrought-like strength for load-critical parts.

"From impossible

to printable"

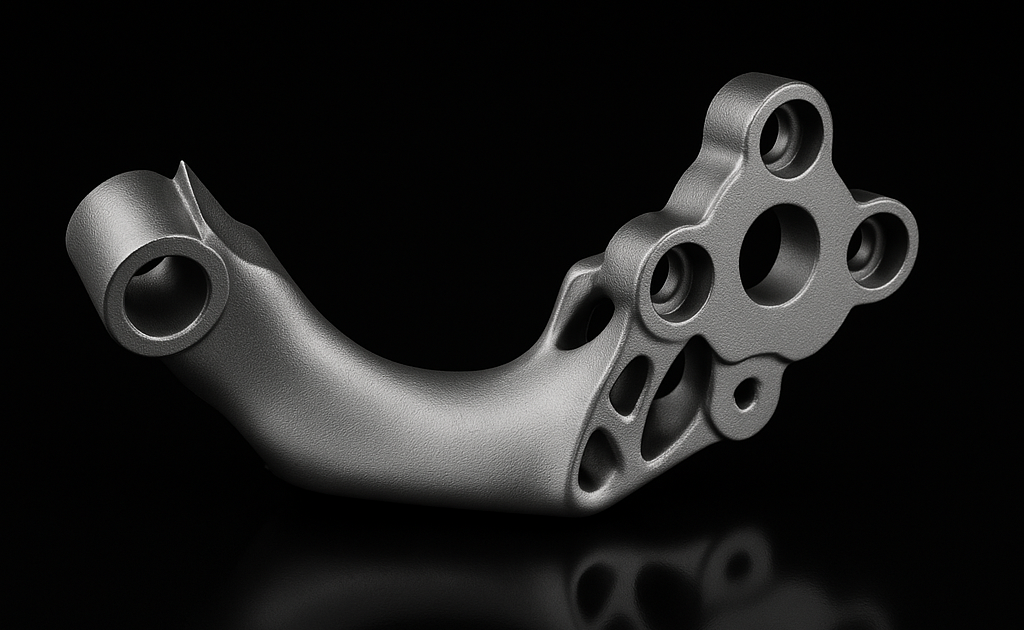

Real-World Applications Enabled by Omnifusion

Omnifusion 3D printing tackles everything from one-off tooling and rapid prototypes to complex, multi-material components. Print intricate geometries, graded metals, and fully assembled parts in hours instead of weeks, slashing lead times and costs.

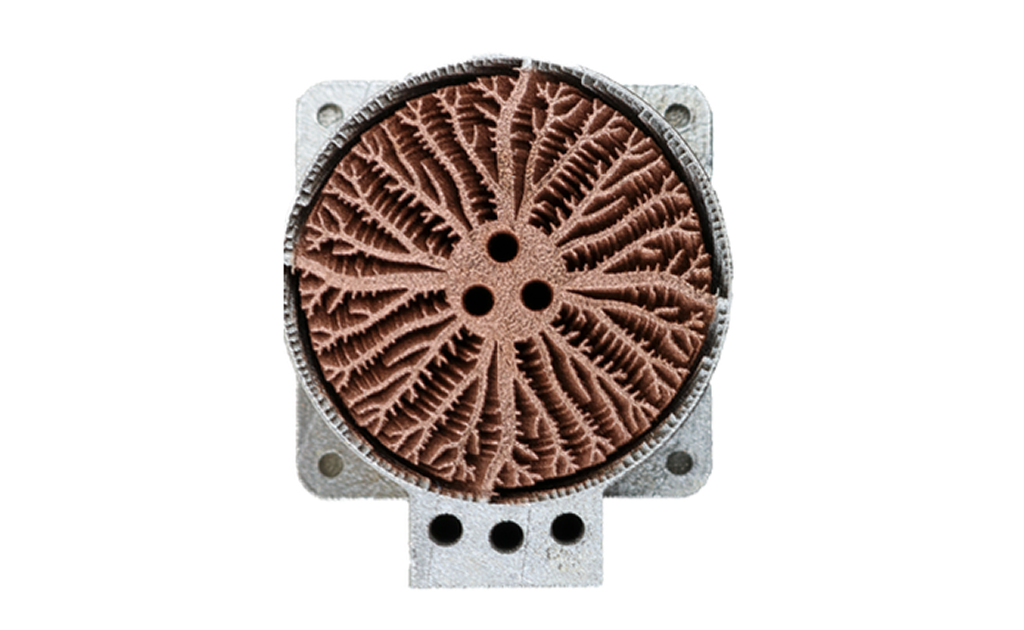

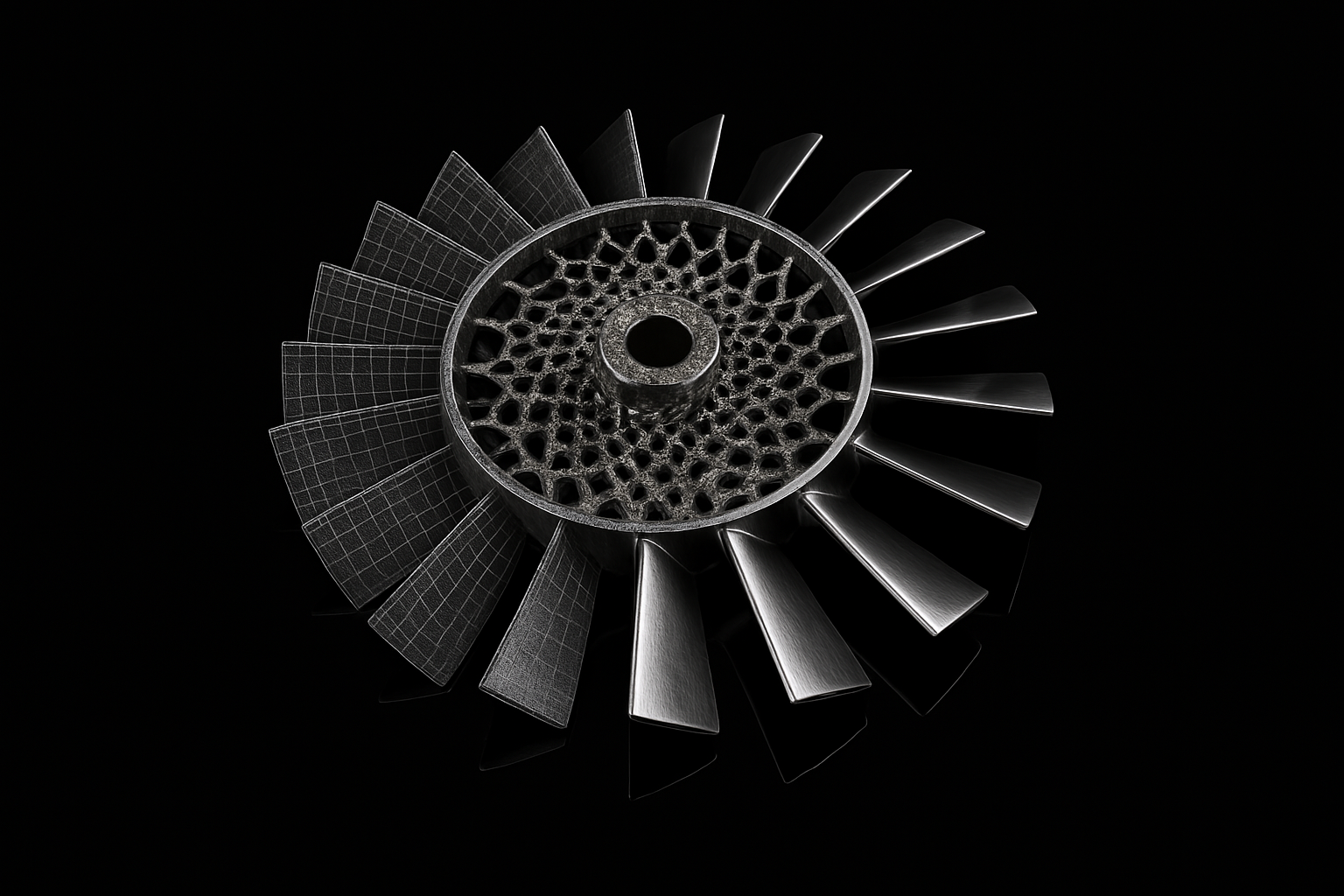

Heat Sink

Organic structure, high surface area for improved cooling and high thermal conductivity with lightweight housing

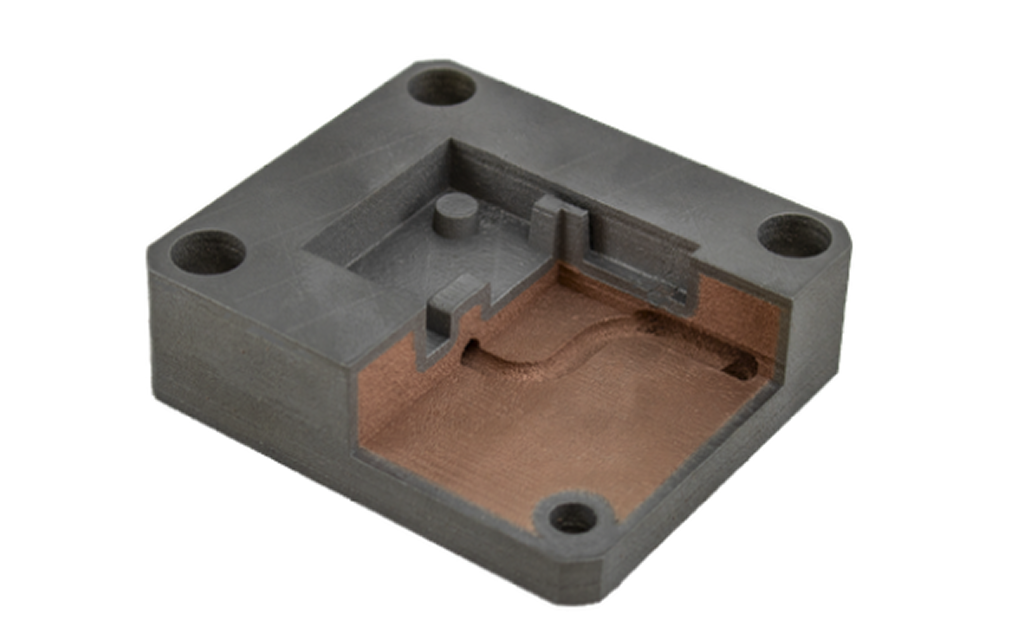

Mold insert

High thermal conductivity, fast availability of near-end-shape semi finish and low waste of tool material

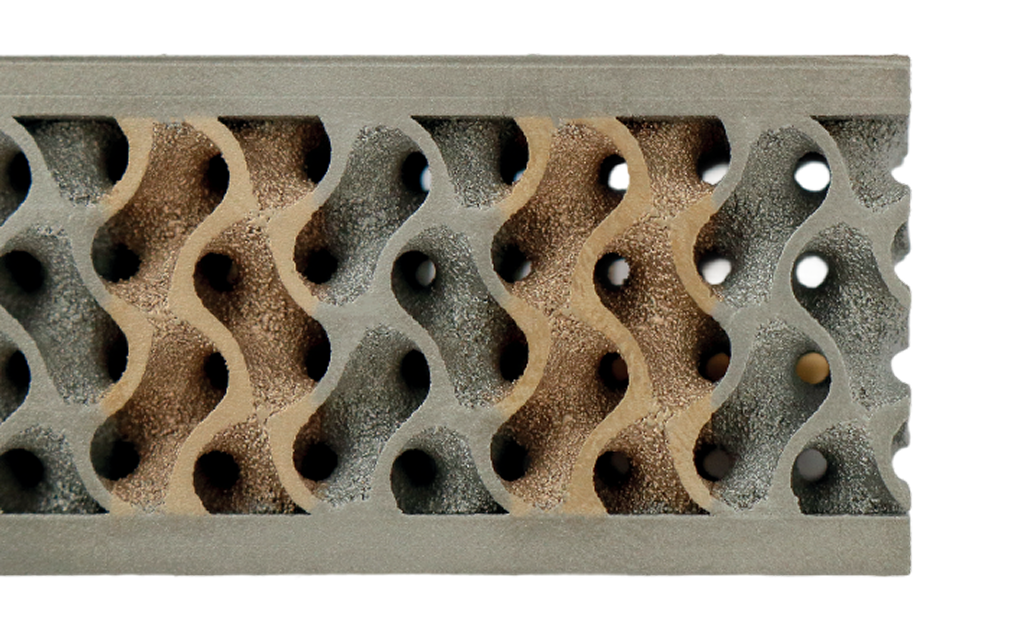

Complex Patterns

Complex geometries impossible with traditional machining—internal cavities, lattice structures, and conformal cooling channels.

And More...

Omnifusion can combine different metals like steel and copper—even ceramics—creating functionally graded parts impossible with traditional manufacturing.

Support That Starts Before the Sale—and Never Stops

From feasibility to full production, our certified team stays accountable for your success.

Pre-Sale Audit

We review your CAD, application goals, and facility constraints to confirm technical fit, ROI, and any site-prep requirements.

Factory-Certified Installation

Our engineers deliver, level, and calibrate your Omnifusion 3D, run first-article builds, and hand over a full acceptance report—so you're productive on day one.

Hands-On Training

In-person or virtual sessions cover build-prep software, machine operation, safety, and QA—ending with operator certification.

24/7 Monitoring & Priority Support

Continuous telemetry spots issues before they happen. You get dashboards, maintenance alerts, and guaranteed tech response times.

Industries We Serve

Explore our expertise across various industrial sectors.

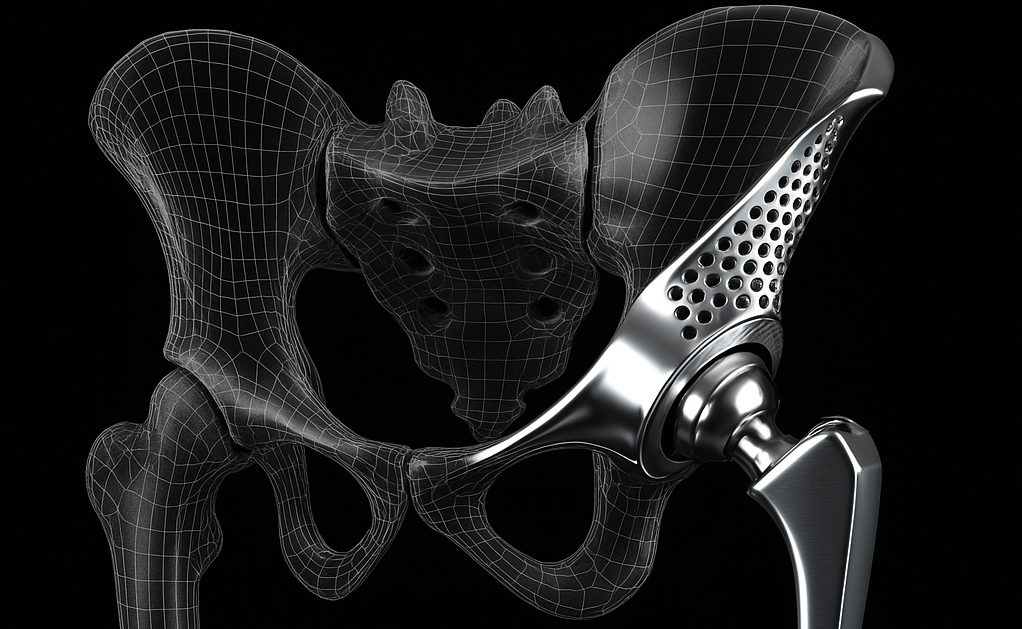

Medical Device

Medical implants and tools

Automotive

Precision components and prototyping

Aerospace

Lightweight components and durable parts

Industrial & Tooling

General CNC and 3D metal printing

Who We Are

Your expert team in multi-material additive manufacturing

Dax Hamilton, Founder

Dax Hamilton, Founder of Dax Research, is a 15+ year veteran in laser manufacturing and has partnered with Schaeffler to deliver its innovative multi-material additive manufacturing to North America.

Schaeffler Group

60 years of experience and a global presence across 13 locations, it offers innovative, scalable manufacturing solutions from concept to volume production.

Introducing the Omnifusion3D Printer

Developed by Schaeffler, the Omnifusion3D represents the next generation in multi-material additive manufacturing

Unique Capabilities

- •Precision laser fusion with unprecedented accuracy

- •Advanced material compatibility for unique combinations

- •Innovative functional integration in products & tools

- •Flexibility in form for individual, free design

- •Reduced lead time, especially for tools & prototypes

Multi-Material Advantages

In many areas, additive manufacturing has established itself as an alternative to conventional production methods. Multi-material 3D printing opens up almost unlimited possibilities, offering:

- •Simplified production of components with complex geometries

- •Reduced material consumption and waste

- •Increased energy efficiency in production

- •More environmentally friendly material options

Technical Specifications

| Specification | Details |

|---|---|

| Deposition width | 250 mm / 4.53 inches |

| Layer thickness | 40 µm - 150 µm |

| Recoating speed | Up to 50 mm/s / 1.97 inches/s |

| Integrated powder containers | 750 ml per drum (3 drums) |

| Recoater size | 480 x 361 x 182 mm / 18.9 x 14.2 x 7.2 inches |

| Powder pixel resolution | 300μm for recoater and die filling platform |

Omnifusion3D Applications

Tool Components

Injection molding insert

- • High thermal conductivity

- • Fast availability of near-end-shape semi finish

- • Low waste of tool material

Welding brackets

- • High wear resistance and thermal conductivity

- • Minimal material waste

Products

Heat sink

- • Organic structure

- • High surface area for improved cooling

- • High thermal conductivity with lightweight housing

Medical implants

- • Innovative joint materials

- • Right material at the right place

Prototypes

Hydrogen applications

- • Increased integration level

- • Reduction of precious materials

- • Controlled porosity

Electric motor coil

- • Fully flexible design

- • Fast component availability